TI launched the brushless DC motor drive series with trapezoidal and FOC control modes

Time:2023-03-02

Views:1220

Are you distracted by the noise caused by many electrical appliances in your home? TI‘s latest brushless DC motor driver adopts trapezoidal and field-oriented control, which can reduce the electrical noise by 3.3 dBA.

Brushless DC motor (BLDC) replaces AC induction motor and is more and more widely used in general electrical appliances, including fans, air purifiers, washing machines and dryer pumps, and medical CPAP blowers.

However, the modulation of brushless DC motor will also produce noise, especially the open concept is more and more popular in the office and home environment.

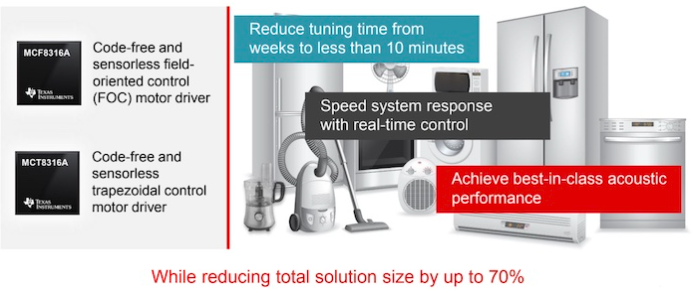

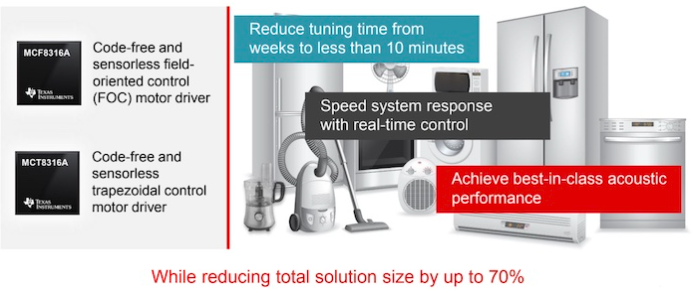

In order to solve these noise-related problems, Texas Instruments (TI) recently announced the launch of two new 70W sensorless brushless DC motor drivers, MCT8316A and MCF8316A. These drives are highly integrated and code-free, and use advanced ladder control and field-oriented control (FOC) respectively.

Several examples of common noise levels of electrical appliances.

The goals of these new chips include three aspects: reducing the sound noise sources in daily applications, reducing the size of the solution by 70%, and reducing the overall design time of BLDC tuning (which may be reduced to 10 minutes).

Let‘s see how TI‘s latest products achieve these three goals.

Overview of MCx8316A chip

MCT8316A and MCF8316A support the working range from 4.5 V to 35 V, with peak output up to 8 A. These chips are designed for speed control of 12 V to 24 V brushless DC motors or permanent magnet synchronous motors.

MCX836A chip overview.

An important feature of the MCX836A series driver is the reduction of noise. Specifically, MCT8316A supports 120 ° and 150 ° modulation and improves acoustic performance through trapezoidal control scheme.

MCF8316A adopts FOC scheme and uses automatic dead time compensation to reduce the harmonic content fed to the motor, thus reducing the noise within the audible range.

One series, two chips and two control schemes, so two popular control schemes can be flexibly realized

Introduction of trapezoidal control and FOC control mode in brushless DC motor

There are two types of brushless DC motor, including Hall effect sensor driving structure and sensorless structure. Although more complex, sensorless architecture is the preferred choice. There are two control schemes for sensorless operation.

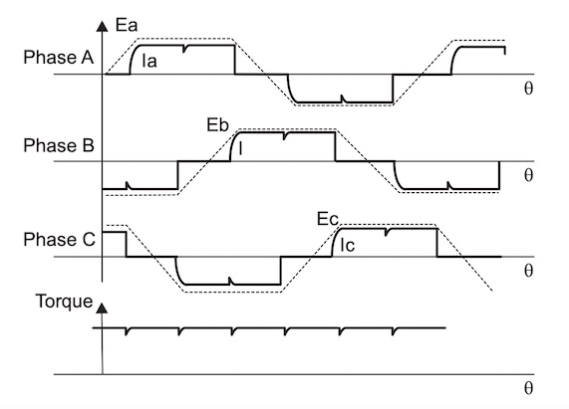

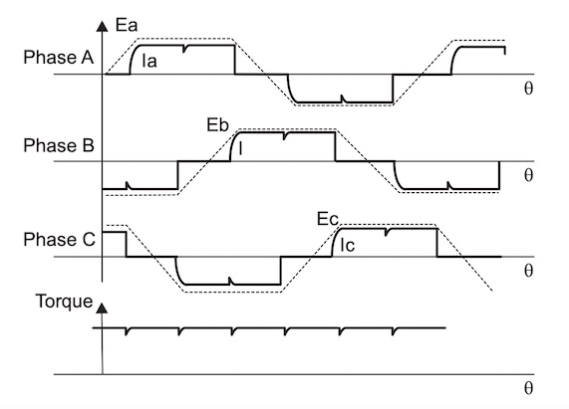

Sequence diagram of ladder control scheme.

The working principle of ladder control is that there are two phases at any given time. Therefore, as shown above, no torque will be generated during zero-crossing of any phase.

This scheme will cause ripple at every 60 ° zero-phase intersection, resulting in harmonics. In 120 ° mode, the BLDC drive will use the high Z state at the remaining 60 ° of each cycle.

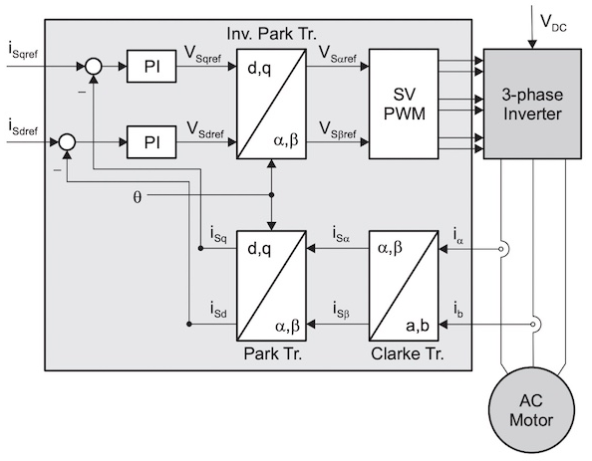

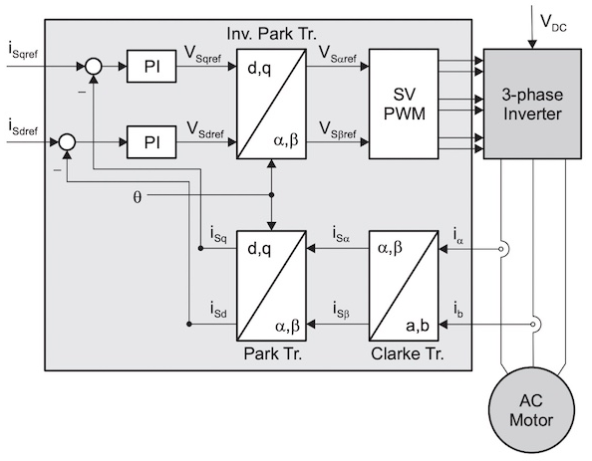

The output of three-phase inverter generates sine signal, which is sampled and fed through Clark transform and Parker transform.

Basic block diagram of field directional control FOC.

Both of these transformations realize direct torque control by converting the stator current vector from a three-phase time-varying system to a two-coordinate time-invariant system.

How to reduce noise of MCX836A chip

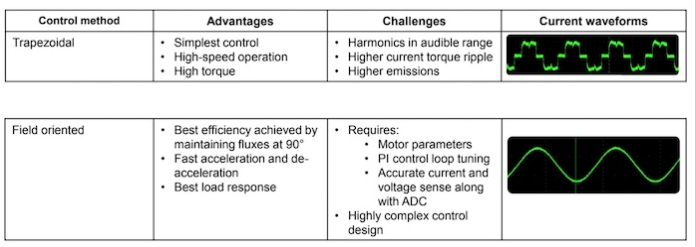

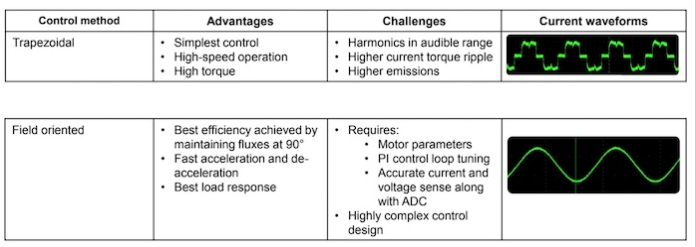

The two control schemes used to control brushless DC motor have their own advantages and disadvantages. Each method will generate harmonics, which will generate noise.

Comparison of advantages and disadvantages of two sensorless brushless DC control schemes.

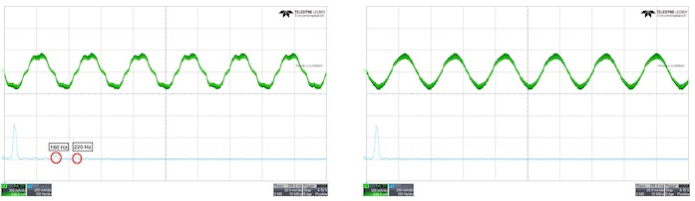

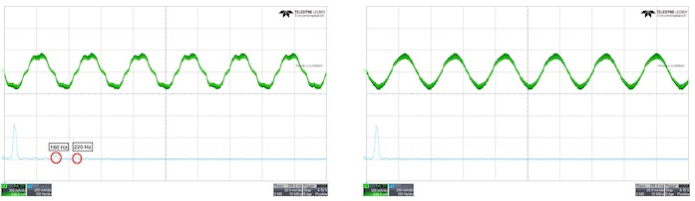

Modulation and dead-time compensation are very important to reduce motor motion noise. MCF8316A uses the resonant controller to compensate the dead time between the high-voltage side and low-voltage side switch MOSFETs to reduce the harmonic content to zero.

Enabling dead-time compensation inside MCF8316A can eliminate audible harmonics (left), resulting in a more pure sine signal (right).

The effect on the sine output and subsequent Fast Fourier Transform (FFT) is shown above.

Similarly, the FFT response of the trapezoidal control scheme (such as MCT8316A) is improved by using the chip‘s variable commutation scheme to dynamically switch between 120 ° and 150 ° by "windowing" the amount of time when the motor phase is in the high Z mode.

In a word, this noise reduction solution seems to be promising in many applications, especially in consumer goods.

Write at the end

Although many employees have not worked in the office for some time, it is easy to recall how environmental noise can distract us. Perhaps even if you work at home, the noise of the refrigerator will also interfere with your work.

The progress of trapezoidal and FOC control schemes is committed to eliminating the fluctuation of the signal driving the brushless DC motor, thus creating a quieter operating environment.

The advanced integration provided by the MCX836A series reduces the solution to 10 components with an area of only 2 cm ², In the discrete scheme, 28 components with an area of 7 cm will be used ²。

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |