如何使LED灯泡可调光

发布日期:2023-01-20

点击次数:1369

多年来,制造商不断向市场推出LED灯,其最终目标是要用来取代白炽灯和紧凑型荧光灯(CFL)。这些灯泡设计的演变经历了从非常简单的不可调光方案,到高级但昂贵的可调光方案,再到性价比更高的可调光方案。

许多LED灯都宣称可调光,但实际上,很多LED灯的性能并不十分理想,且由于所使用的调光器和电路负载不同而性能各异。有时,将LED灯安装在设有调光器的室内后,LED灯会出现闪烁且无法均衡调整光亮度的情况。

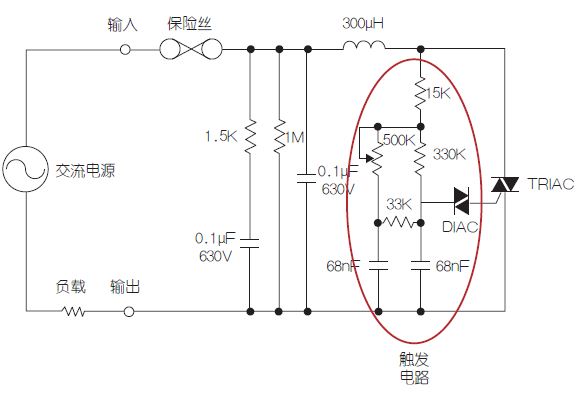

这些缺陷是由于现阶段美国使用的大部分调光器都是基于双向晶闸管(TRIAC)二线前沿切相电路的,这些电路开发于20世纪60年代,适用于电阻式白炽灯。TRIAC是一种双向半导体电源开关,由可变定时电路生成的脉冲触发,并在传导电流高于保持电流时维持导通。调光器电路的种类有很多,使用了不同特性的器件以及不同的控制电路和滤波元件。

LED灯的驱动器电路将交流输入电源转换为低压直流电源,并维持一个稳定电流,驱动高亮度LED负载获得恒定光输出。要想通过基于双向晶闸管的调光器来调节基本的LED驱动器电路,就必须额外添加一些元器件来实现稳定的调光器运行,并根据调光器相位角来调节输出电流。

由于调光器差异较大,所连接的LED调光电路性能也有所不同。由于现在还未出台明确标准来划分带有调光器的LED灯泡的性能,使这一问题变得更加复杂。至多会有一些灯泡制造商提供调光器列表,列明他们认为可与其产品兼容的调光器。

在美国能源部(DoE)的支持下,美国电气制造商协会(NEMA)正着手制定适用于由切相调光器驱动的LED灯的调光标准,包括决定是否达到可接受性能的测试程序及指标。希望这一标准最终能够帮助清理掉市场上那些声明可调光,但性能远未达到终端用户所期待的柔和、稳定如白炽调光预期的产品。

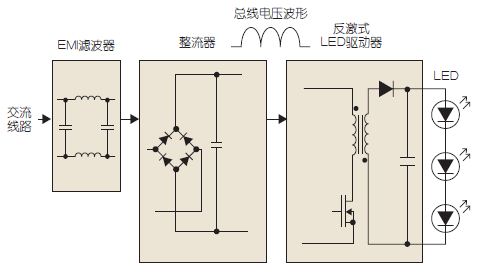

大部分LED灯泡使用的驱动电路都包含降压、升降压或反激式转换器。在各种情况下,都可通过修改基本电路来实现可接受的调光性能,同时不会增加器件的成本和复杂性。这样就可以提升可调光驱动器的性能,进而满足消费照明市场的成本节约要求。

兼容性的问题在于TRIAC调光器电路如何与LED驱动器输入电路进行交互。

单级LED驱动器示例电路(图2)取代了图1中代表白炽灯的电阻性负载。尽管这一电路由于在稳定运行时的高功率因数模拟了电阻性负载,但其前端也包括了EMI滤波所必需的电容器。此外,LED灯泡所消耗的功率比同等白炽灯的25%还要少。结果就是,在TRIAC触发前,调光器在交流线路半周期中主要承受电容性负载。

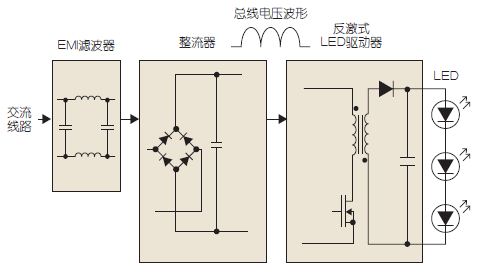

图1:典型的调光器原理图

图2:基本的LED驱动器电路框图

图1所示的双向触发电路若想要按照设计目标运行,还需要一条电阻性路径至中性点。如果改为电容性负载,这一电路将无法正常运行,并导致周期转换时出现不稳定触发的情况,具体表现为输出的光不停闪烁。调光器和LED驱动器中的EMI滤波器,还会由TRIAC启动时的高dv/dt引起振铃振荡。

振荡幅度达到一定程度时,会导致电流降至“保持电流”以下,从而使TRIAC关闭,而无法在下一次线路过零之前维持TRIAC导通。这一情况通常会由于触发电路重触发TRIAC,导致其在单个线路半周期中多次开和关。除了给元器件造成应力并很可能破坏调光器或LED驱动器之外,这将导致出现严重的闪烁以及令人不悦的噪声情况。

假设使用LED灯所适用的调光器来替代该调光器并不是理想的解决方案,那么可以通过修改LED驱动来解决上述问题,从而实现LED驱动与标准调光器的搭配使用。

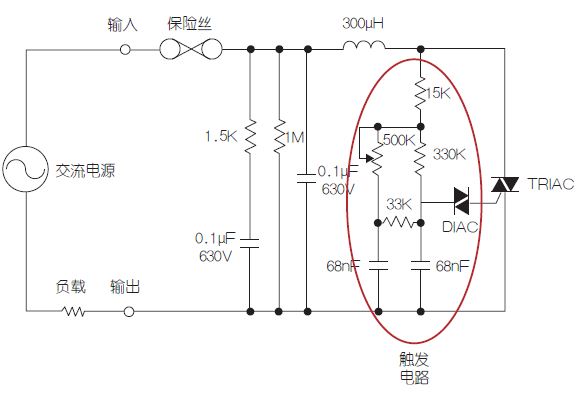

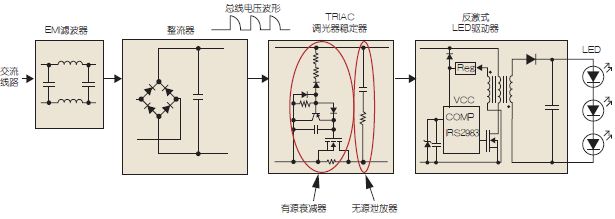

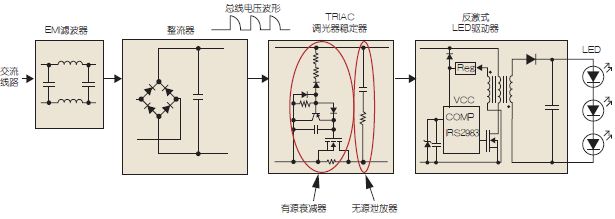

图3:可调光LED驱动示意图。

示例电路(图3)为单级LED反激式转换器,同样的技术也可用于升降压或适应性降压转换器。首先,必须在设计输入滤波器时将输入电容保持在最小值,这样也有助于实现最佳的功率因数。

下一步介绍的是有源衰减器及无源泄放器电路。衰减电路在TRIAC触发时会限制冲击电流,从而极大地抑制振铃,以至TRIAC保持导通状态。短暂延时后,衰减电阻被一个小的MOSFET所旁路,以防止在余下的导通期间产生功率损耗。为将低功率驱动器成本降至最低,可忽略旁路MOSFET及其相关的驱动电路,但这会导致电阻器的散热及相关的效率损失。

可使用无源泄放器电路代替一些调光解决方案中使用的有源泄放器。该串联RC网络从触发点开始传导电流,时间足够开关转换器开始抽取电流,这有助于确保电流在这一期间不会降至保持电流以下。以恒定导通时间运行的反激式或升降压转换器作为接至直流总线的主要电阻性负载,可在下次线路过零前保持调光器TRIAC的导通状态。转换器需要抽取足够多的电流,以保持在TRIAC保持电流之上。单级PFC反激式或升降压转换器通常可以实现这一目标。

此处所述电路采用了IRS2983控制器IC,其运行在电压模式下。COMP输入端上的直流电压电平决定了开关周期的导通时间。因为控制器IC常与初级侧调节一起使用以保持恒定的输出功率,所以必须在这一输入端上增加齐纳二极管来钳位COMP电压。这就对最大导通时间设置了限制,以致在调光期间,当直流总线电压下降时,导通时间就无法增加来进行补偿。

结果就是,随着调光器设置的降低及直流总线电压的下降,输出电流也会降低。这样就可以在无需采用更复杂的电路来检测调光器相位角或调节输出的情况下,通过调节调光器控制将灯光亮度调节至低于20%。同时,必须在调光关闭期间释放控制器VCC电源,以确保IC仅在所需时段运行。为此使用了一个高压二极管连接VCC与直流总线。

有源衰减器及无源泄放器电路也可与降压转换器一起使用,但结果取决于LED电压。由于在线路电压低于输出电压时转换器无法抽取电流,相位调光运行范围将受到限制。出于这一原因,LED电压最好保持较低,但也不能太低,否则电路将变得无效,需要使用过大的电感器。对于保持合理调节范围的120VAC系统,LED电压最好是20V~40V。CCM降压LED控制器IC(如IRS2980)可在不平滑的总线电压始终高于LED总输出电压的同时,维持LED灯的平均电流调节。

本文介绍的这些简单技巧在与所述的LED转换器一起使用时,可使大多数基于TRIAC的调光器实现无闪烁的平滑调光效果。

|

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! |